Understanding The "Sip Chip": Unpacking A Key Piece Of Modern Tech

Have you ever heard the term "sip chip" and felt a little puzzled? It's a phrase that, interestingly enough, can point to a couple of very different ideas, depending on where you hear it. For many, "SIP" brings to mind financial planning, like a systematic investment plan, which is a popular way to invest in mutual funds regularly over a period of time. You know, where a sip calculator helps you figure out potential returns from your investments, providing an approximate future value based on things like the amount you put in, how long you invest, and the expected rate of return. Manually calculating sip returns can be complicated, as each monthly contribution has a different holding period. So, it's almost like a financial tool that helps people grow their money.

But then, there's another "SiP," one that's a very big deal in the world of electronics. This one, often called a "System in Package," or SiP for short, is about how computer parts are put together. It's a method for packaging different electronic parts, like processors, memory, and sensors, into one single unit. This kind of "sip chip" is pretty common in devices we use every day, especially those that need to be small and powerful, like your smartwatch or smartphone, that's for sure.

So, when we talk about a "sip chip," we're usually thinking about this clever way of putting many functions into one compact package. It’s a key part of making our gadgets smaller and more efficient, allowing for some really neat advancements in technology. We will explore this technological marvel, its components, how it works, and why it matters for the future of electronics, and then some.

- Ann Blyth Age

- Missi Pyle Feet

- Sophie Rain Onlyfans Worth

- Savvy Suxx Emanuel Lustin

- Chucky Wackem Net Worth

Table of Contents

- What is System in Package (SiP) Technology?

- How SiP Chips Work

- Why SiP Chips Are Important

- Real-World Applications of SiP Chips

- The Future of SiP Technology

- Common Questions About SiP Chips

What is System in Package (SiP) Technology?

A System in Package, or SiP, is a way to put many different electronic components together into one standard package. This means you can take several active electronic parts, which do different jobs, and sometimes even passive parts, and connect them all inside a single enclosure. This creates a functional unit, which is pretty clever, you know.

The core idea behind SiP is to get more performance and features into a smaller space. Instead of having separate chips for everything on a circuit board, a SiP combines them. This is particularly useful for things that need to be very small, like the tiny computers found in smartwatches or medical devices, as a matter of fact.

It's a step beyond just having one chip do one thing; it's about making a whole system fit into a single, compact package. This helps reduce the overall size of electronic products, which is a big deal for today's gadgets, obviously.

- Rarest Squishmallows List

- Dubai Bling Cast

- Jim American Pie Dad

- Jake Paul And Logan Paul Twins

- Steel Grey Eyes

SiP vs. SoC: Understanding the Difference

It’s important to see how SiP is different from something called a System on Chip, or SoC. An SoC is a single chip that has many different functional parts, like a processor, memory, and connections, all built directly onto that one piece of silicon. It's like having a whole mini-computer etched onto a single silicon wafer, which is pretty neat.

The main technical difference is that SiP is about putting existing, separate chips and other parts *together* in one package. An SoC, however, is about making all those different functions *on* a single chip. Think of it this way: an SoC is a single, very complex chip, while a SiP is a collection of several chips and other parts bundled into one neat package. So, SiP packaging is like combining existing chips, that's what it is.

Both SiP and SoC aim to make electronics more compact and efficient. But they achieve this goal in different ways. SiP offers more flexibility, allowing engineers to mix and match different kinds of chips and technologies, which can be very helpful for specialized products, you know.

How SiP Chips Work

Making a SiP involves carefully putting various electronic parts inside a single protective case. This process is quite precise, ensuring all the different pieces connect correctly and work well together. It’s like building a tiny, intricate city within a small box, that's what it is.

The way these parts are connected can vary. Sometimes, they are stacked one on top of another, which saves a lot of space. Other times, they are placed side-by-side on a small base. The goal is always to make the whole assembly as small and efficient as possible, which is a big challenge, certainly.

The final SiP package protects the delicate components inside from damage and helps them manage heat. This packaging is a crucial part of the overall design, making sure the "sip chip" can perform reliably in real-world products, that's for sure.

Components Inside a SiP

A SiP can hold many different kinds of parts. Typically, you might find several integrated circuits (ICs), which are the actual "chips" that do specific tasks, like processing information or storing data. But it's not just ICs, you know.

It can also include passive components, like resistors and capacitors, which control electrical flow. Sometimes, even tiny sensors, antennas for wireless communication, or even micro-electromechanical systems (MEMS) are put into a SiP. This ability to combine so many different functions is what makes SiP so powerful, obviously.

The exact mix of components depends on what the "sip chip" needs to do. For a smartwatch, it might have a processor, memory, a motion sensor, and a wireless chip all in one SiP. For a medical device, it could contain specialized sensors and a low-power processor, which is pretty versatile, you know.

The Assembly Process

Putting a SiP together is a complex manufacturing process. It starts with individual components, often called "dies," which are the raw silicon chips before they are packaged. These dies are very thin and delicate, that's for sure.

These dies are then attached to a substrate, which is a small base that provides electrical connections. This attachment can be done using tiny wires (wire bonding) or by placing small solder bumps directly onto the connections (flip-chip bonding). The choice of method depends on the specific design and performance needs, which is a key decision, you know.

After the components are attached, the whole assembly is enclosed in a protective material, usually a plastic or ceramic compound. This encapsulation protects the components from moisture, dust, and physical damage, and helps to dissipate heat. It’s a bit like creating a tiny, sealed fortress for the electronics inside, that's what it is.

Why SiP Chips Are Important

SiP technology is a big deal because it helps overcome some challenges in making smaller, more capable electronic devices. As we demand more features in tinier gadgets, simply shrinking individual chips becomes harder and harder. SiP offers a clever way around this, you know.

It allows product designers to pack more functionality into a limited space without having to redesign every single component from scratch. This speeds up the development process and can even make manufacturing more cost-effective in some cases, which is a significant advantage, obviously.

The flexibility of SiP also means that different technologies, even those made with different manufacturing processes, can be combined. This is a powerful capability, allowing for highly customized and specialized electronic solutions, that's for sure.

Benefits for Device Makers

For companies that make electronic devices, SiP brings several important advantages. One of the biggest is space saving. By integrating multiple functions into one package, the overall size of the product can be greatly reduced, which is crucial for wearables and portable devices, you know.

Another benefit is faster time to market. Instead of spending a lot of time designing a single, complex SoC, companies can use existing, proven chips and integrate them into a SiP. This can speed up the development cycle, getting products to consumers quicker, which is a real plus, certainly.

SiP can also improve performance by shortening the distances between different components. Shorter connections mean faster communication between chips and less power loss. This can lead to more efficient and responsive devices, which is something everyone wants, you know.

Advantages for Consumers

For us, the people who use these devices, SiP technology means better products. We get smaller, lighter gadgets that can do more things. Think about how much computing power is packed into a modern smartphone or smartwatch; SiP plays a big part in that, that's for sure.

These devices also tend to be more energy-efficient, meaning longer battery life. Because the components are so close together in a SiP, less energy is wasted in transmitting signals between them. This is a welcome improvement for anyone who relies on their portable electronics throughout the day, which is most of us, obviously.

Ultimately, SiP contributes to a world where technology is more seamlessly integrated into our lives, providing powerful tools in convenient, compact forms. It makes advanced features accessible in devices we carry with us everywhere, which is pretty amazing, you know.

Real-World Applications of SiP Chips

SiP technology is already everywhere, even if we don't always see it. One very clear example mentioned in our reference text is the iWatch. The Apple Watch, in fact, uses SiP extensively to pack all its complex features into a tiny space on your wrist. This allows for health tracking, communication, and apps, all from a small device, which is quite impressive, certainly.

Beyond wearables, SiP is also found in many other areas. Smartphones use SiP to combine various wireless modules, processors, and sensors. This helps make them thin and powerful, which is what users expect, you know.

Medical devices, like hearing aids or portable diagnostic tools, often rely on SiP for their compact size and specialized functions. In automotive electronics, SiP can integrate sensors and control units into smaller, more robust packages. It's truly a versatile technology, that's for sure.

Even in industrial settings and the Internet of Things (IoT) devices, SiP plays a role. It enables the creation of small, low-power sensors and communication modules that can be deployed in many different environments. This helps connect more things to the internet, creating smarter systems, which is pretty important, you know.

The Future of SiP Technology

The road ahead for SiP technology looks very promising. As devices continue to shrink and demand more capabilities, SiP will likely become even more important. We can expect to see SiP packages becoming even denser, with more components packed into the same or smaller spaces, which is a constant push, you know.

There's also a growing trend towards integrating different types of materials and technologies within SiP, such as optical components for faster data transfer or even micro-fluidic systems for specialized applications. This kind of integration opens up new possibilities for what these "sip chips" can do, which is quite exciting, certainly.

The development of new manufacturing techniques will also help SiP evolve, making it more efficient to produce and even more versatile. As the lines between different electronic functions blur, SiP offers a flexible way to bring them all together into cohesive, powerful units. It’s a technology that truly enables the next generation of smart devices and systems, that's for sure.

Common Questions About SiP Chips

People often have questions about SiP technology, especially given the similar-sounding financial term. Here are some common inquiries:

What is the main advantage of a SiP over a traditional circuit board?

The biggest advantage of a SiP is its ability to save space. By putting many components into one package, it makes electronic devices much smaller and lighter. This is very helpful for gadgets like smartwatches or tiny sensors, you know. It also improves performance by shortening the paths signals travel, which is a real plus.

Is SiP more expensive to make than a System on Chip (SoC)?

The cost comparison between SiP and SoC can be complex and depends on many factors. For very high-volume products where all functions can be integrated onto a single chip efficiently, SoC might be more cost-effective. However, for specialized products or those needing to combine different technologies, SiP can sometimes be less expensive because it uses existing, proven chips, which saves on new chip design costs, you know. It really varies by project, that's for sure.

Where can I find more information about SiP technology?

You can find a lot more about System in Package technology from various industry publications and academic papers. For a good starting point on the technical aspects, you might look into resources from organizations like IEEE or semiconductor industry associations. You can also learn more about advanced packaging technologies on their sites. Also, learn more about innovative tech solutions on our site, and link to this page for more articles on electronics.

- Do Herons Eat Ducklings Uk

- Theodore Barrett Press Secretary For Which President

- Rob Roberson Nfl

- Volume Eyelash Extensions

- Being Human Lyrics Shinedown

Ladies Chip & Sip - Meadow Creek Golf Course

Sip and Chip - Twin Lakes Village Golf Course

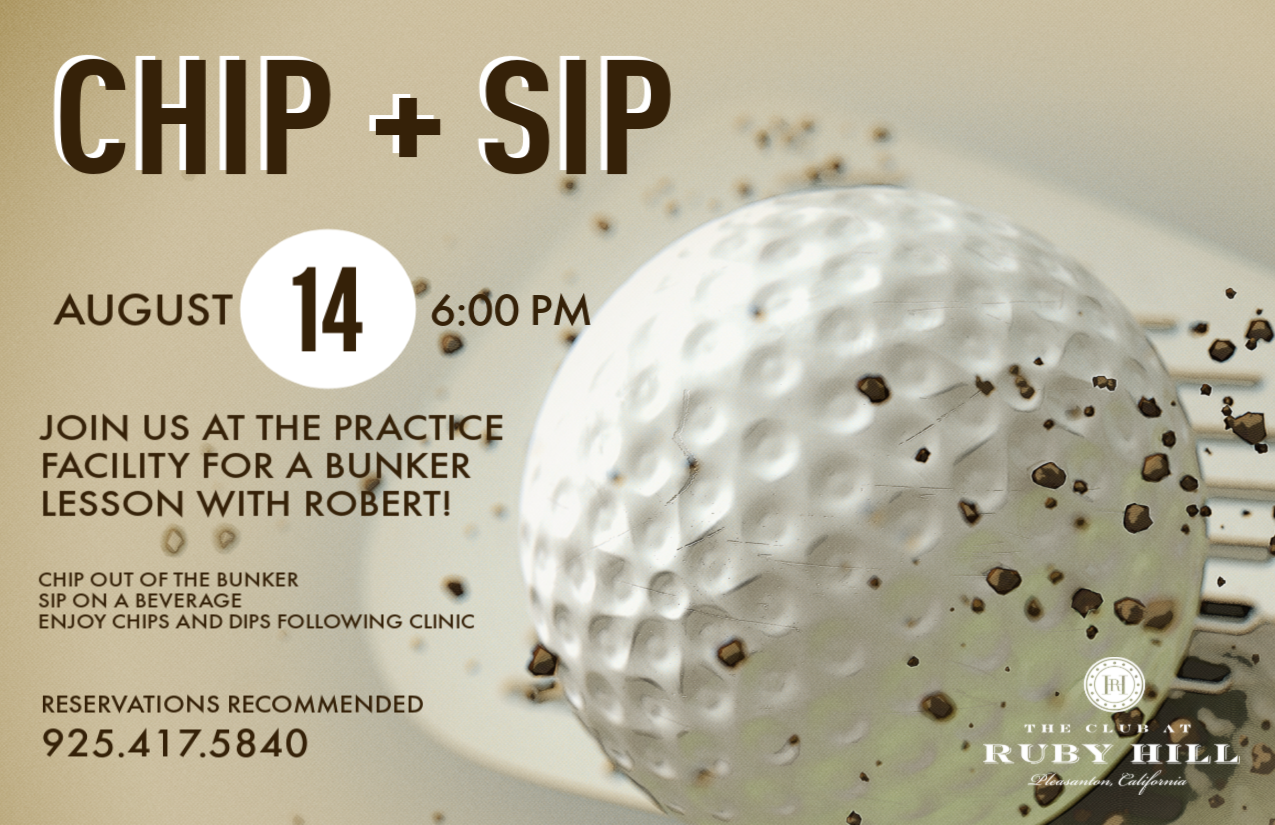

Chip & Sip | The Club at Ruby Hill | 2019-08-14